Kinematics kit „Kim“

Introducing our Kinematics Kit „Kim“, the gateway to crafting

personalized robots with unmatched mechanical flexibility. With

„Kim,“ you‘re not just building a robot; you‘re sculpting an

innovative creation that reflects your unique vision.

Designing your robot is intuitive: simply choose the components you

need—whether it’s the computing unit (like a Raspberry Pi or another

system), the number and type of motors for wheels, arms, or other

moving parts, and your preferred power source. The Kinematics Kit

adapts to your ideas. Every component is modular, stackable, and

expandable, giving you the freedom to configure your robot exactly

the way you want it.

At the heart of the kit lies either Ethernet compatible adapter

board or Raspberry Pi compatible adapter board, the raspberry pi

compatible adapter board, seamlessly integrating with your setup for

effortless connectivity. Motor control becomes a breeze with direct

plug-in compatibility for up to 8 encoder DC motors, granting you

precise command over your robot‘s movements. Power management is

streamlined with the included module featuring on/off logic and

efficient battery pack management allowing Hot Plug connectivity.

Say goodbye to power concerns and hello to uninterrupted

experimentation. Additionally, the auxiliary power supply module

elevates your capabilities by offering supplementary voltage levels

for extra devices, expanding the horizons of what your robot can

achieve.

tech specs

Enquireconfigurations

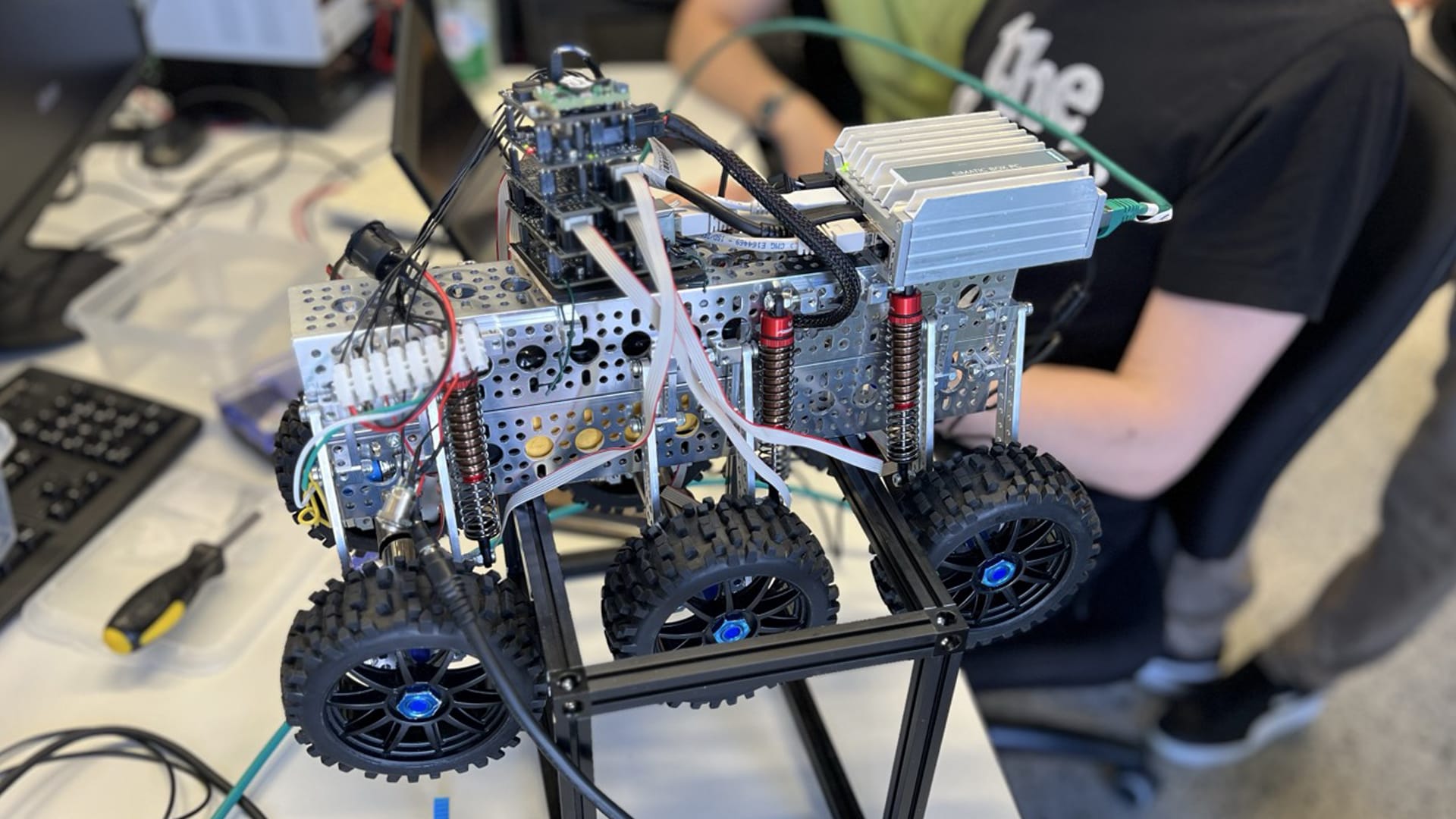

Kim is designed for full flexibility — its modular architecture

allows you to tailor every build to your specific needs. Whether

you're developing an industrial robot, a mobile research platform,

or an educational prototype, the system adapts to you.

The animation shows one example configuration, highlighting the

core stack of the system. As you can see, all the boards are

stackable and connect seamlessly with each other, forming a

compact and expandable unit. The bottom board is interchangeable:

it can either be an Ethernet adapter board, as shown—ideal for use

with industrial computers like the Siemens Simatic IOT—or a

Raspberry Pi combined with a dedicated adapter board that

integrates the Pi into the stack.

Depending on your requirements, you can attach two motor

controller boards to power four high-torque motors—perfect for

heavy-duty applications—or expand to four motor controller boards

to drive up to eight smaller motors, ideal for robots with 6 or 8

wheels where flexibility and mobility are key.

No matter your setup, Kim’s modularity makes complex robot

configurations easy to build, expand, and adapt.

components

Ethernetboard

This Ethernet Adapter Board serves as a versatile Ethernet controller, available either as a plug-in module for Raspberry Pi 4/5 or as a standalone Ethernet interface board. It enables any computer with an Ethernet port to control the EduArt robot—offering flexibility in computing power placement. The board is designed to receive power via circuit board socket strips and accepts input voltages ranging from 12 V to 55 V. Depending on your motor setup, a high-current power source (at least 8 A) is recommended.

EnquireRaspberry Pi 5 with Softwareimage

The EduArt drive system can be operated using a Raspberry Pi 4 or 5 with a pre-configured software image. This image contains all necessary ROS 2 drivers, configurations, and control software, allowing the robot to be up and running within minutes. The Raspberry Pi connects directly to the robot’s control electronics, handling motor commands, sensor integration, and system monitoring. This all-in-one solution is ideal when the computing power is mounted directly on the robot rather than connected via Ethernet from an external computer.

EnquireRaspberry Pi Adapterboard

Our adapter board can be plugged directly onto a Raspberry Pi 4 or 5, or used as a standalone EduArt Ethernet Controller. This allows you to connect any computer with an Ethernet interface and tailor your robot’s computing power precisely to your application. Power is supplied via the pin headers. For this, we recommend using a PCB with matching sockets for a power supply unit or battery. The board supports input voltages (Vin) from 12 V to 55 V. Depending on the number of motors connected, your power source must be able to deliver higher currents. For robotic applications, we recommend high-current batteries with a minimum output of 8 A.

Enquire2 Channel Motorcontroller

The Motorcontrollers can be plugged in directly. This allows you to control the speed of 1 to 8 motors. The motor controllers are available in two versions, single-channel or dual-channel. Up to four motor controllers can be used, i.e. it is possible to use 1 to 4 larger motors (IRMS up to 5A) or 1 to 8 smaller motors (IRMS up to 2.5A). The dielectric strength of the single-channel motor controllers is 55V. The dielectric strength of the dual-channel motor controllers is 35V.

EnquirePower Management

The Power Management Module takes over the charge control of a 19.2V NiMH battery pack and also offers an on/off logic. Temperature monitoring of the battery uses an integrated 6.8kOhm NTC. Never connect a battery other than the one supplied by EduArt.

EnquireAUX Power Supply

The Auxiliary Power Supply Module provides additional voltage levels with which you can supply additional devices. The permissible operating voltage is between 15V and 36V.

Warning: The Raspberry single-board computer is supplied directly via the socket connectors. Never connect an external power supply for the Raspberry via USB-C.

downloads and links

usage in the educational project RobotsUnite(!)

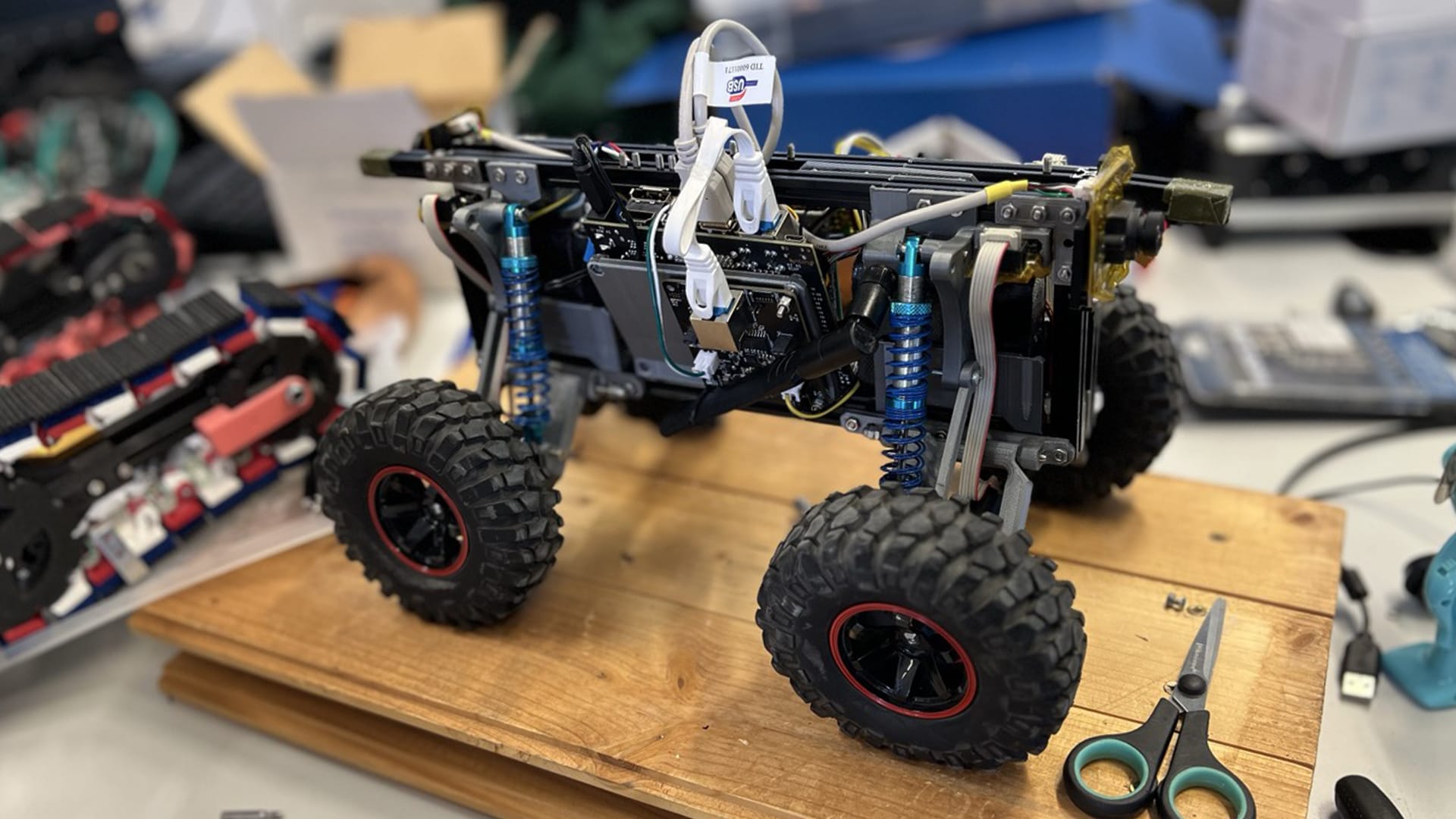

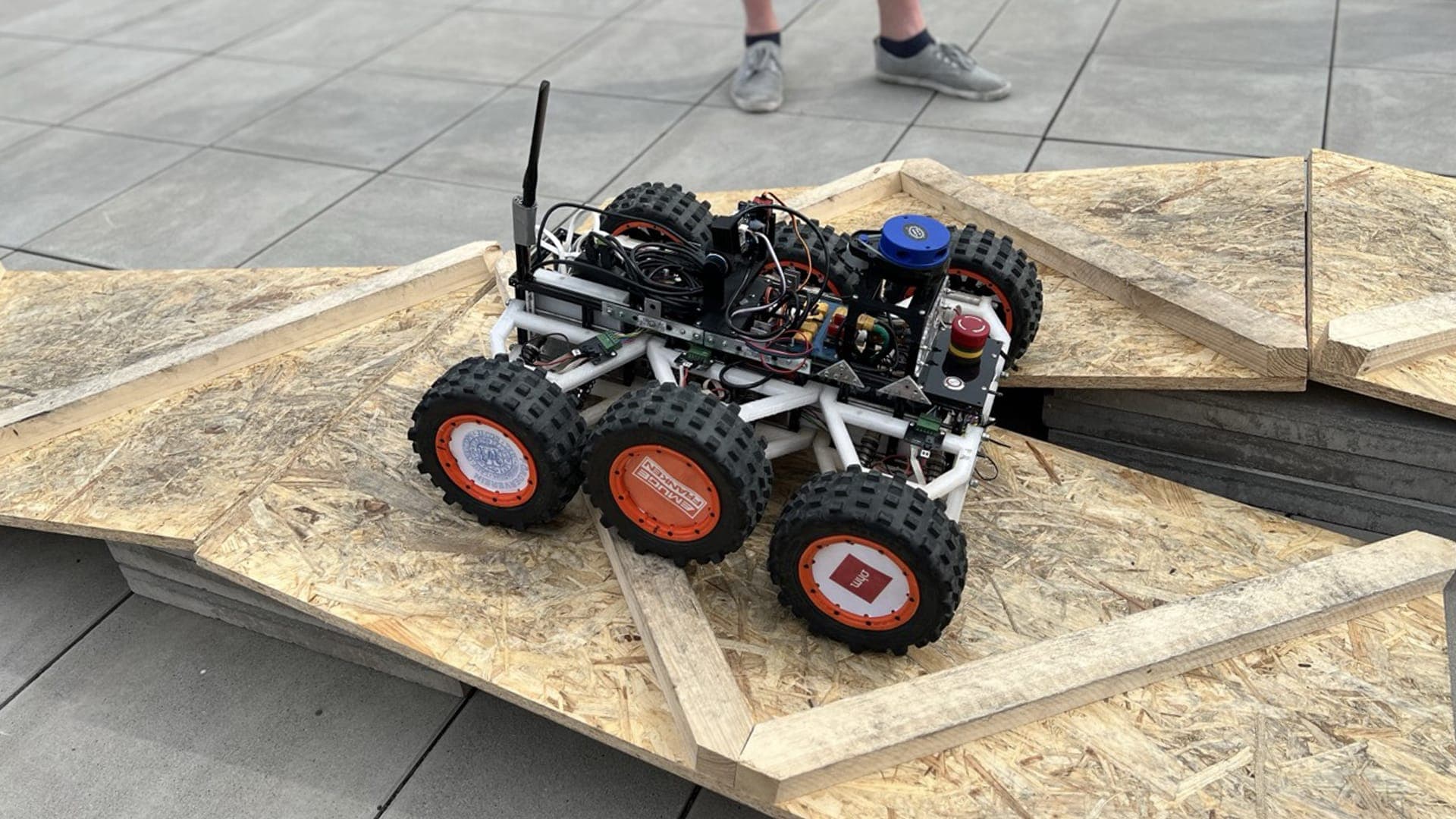

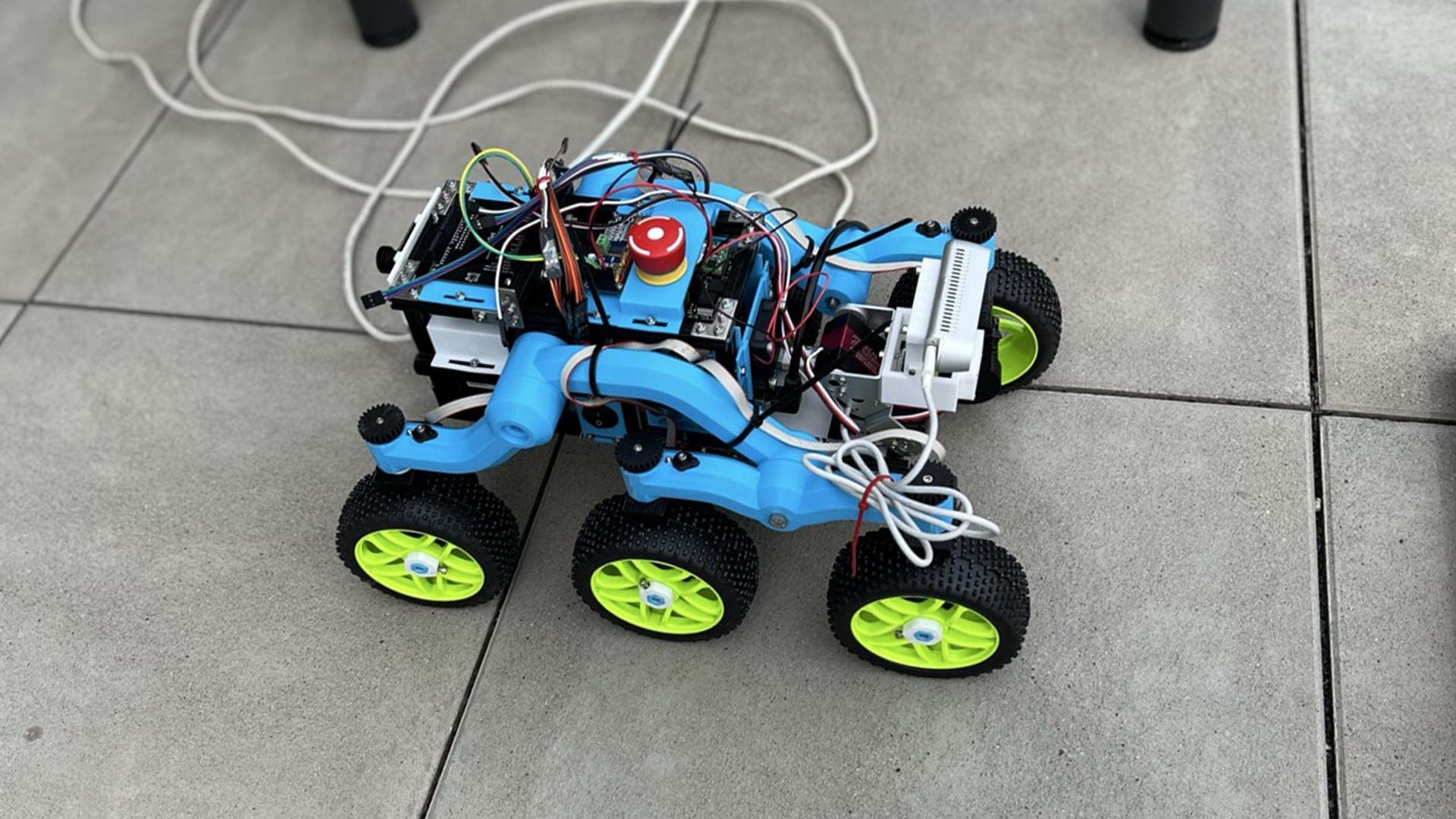

The KinematicsKit Kim is actively used in the educational project

RobotsUnite(!), where students are sponsored with a basic version of

the kit to build their own robots. They receive support through an

online forum where they can ask questions, share ideas, and get

technical assistance. Many of the student-built robots even compete

in the student league of the official RoboCup World Championship

(RMRC).

This collaborative project brings together students from different

schools. Each school develops its own mobile robot as well as

challenging obstacles and tasks. The unique aspect: no single robot

is able to complete the tasks on its own. Since each school only

contributes one robot, teams from different schools must unite to

solve the challenges—reflecting the dual meaning of the project

name: „Robots unite!“ = „Robots, unite!“ or „Robots unite (pupils).“

At each participating school, students are divided into two groups.

The Robotics group designs and builds a mobile, all-terrain robot

using the KinematicsKit Kim, while the Challengers group focuses on

developing creative and technically demanding obstacles that all

robots must overcome during the competition.

On competition day, robots from different schools team up to face

the obstacles designed by the Challengers. The event uses a

competitive point system: Robotics teams earn points for overcoming

obstacles, while the Challengers lose points accordingly. However,

the Challengers’ score cannot drop below half of their starting

value to remain eligible for victory.

This unique format encourages not only technical learning, but also

teamwork across school boundaries—making RobotsUnite(!) a project

where both robots and students truly come together.