Sensor ring „Vision360“

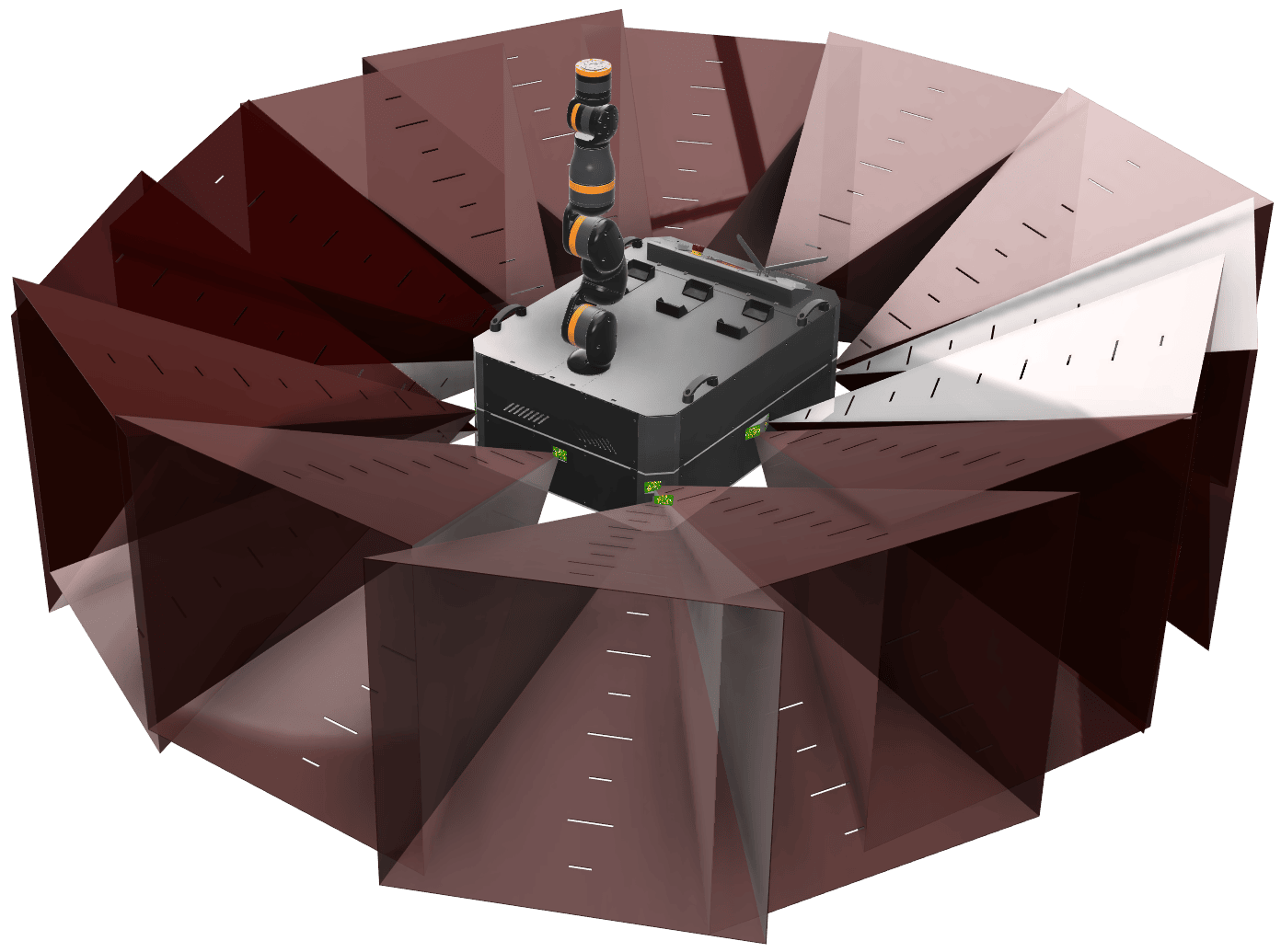

The Vision360 3D ToF Sensor offers advanced obstacle detection for enhanced robotic navigation and safety. This modular sensor ring is designed for seamless daisy-chaining, allowing for flexible configurations tailored to the specific shape and dimensions of various robotic platforms.

This adaptability makes it ideal for comprehensive collision avoidance systems, enabling multi-level detection that simultaneously identifies objects like people and forklift tines — objects that traditional sensors often miss because they only scan in two dimensions and fail to detect objects outside the scan plane.

Unlike standard sensors with limited 270° detection, the Vision360 setup with up to 81 sensors delivers full 360° coverage, supporting omnidirectional driving and ensuring safety in all directions. Key features include underrun protection and fall protection, making it a complete solution for advanced industrial and autonomous applications.

In addition to its technical strengths, Vision360 offers clear cost advantages. The modular design means you only buy the sensors you need, reducing hardware costs while maintaining full coverage. With no moving parts, maintenance is minimal, and energy-efficient operation further lowers total cost of ownership.

tech specs

Download Technical Datavariants

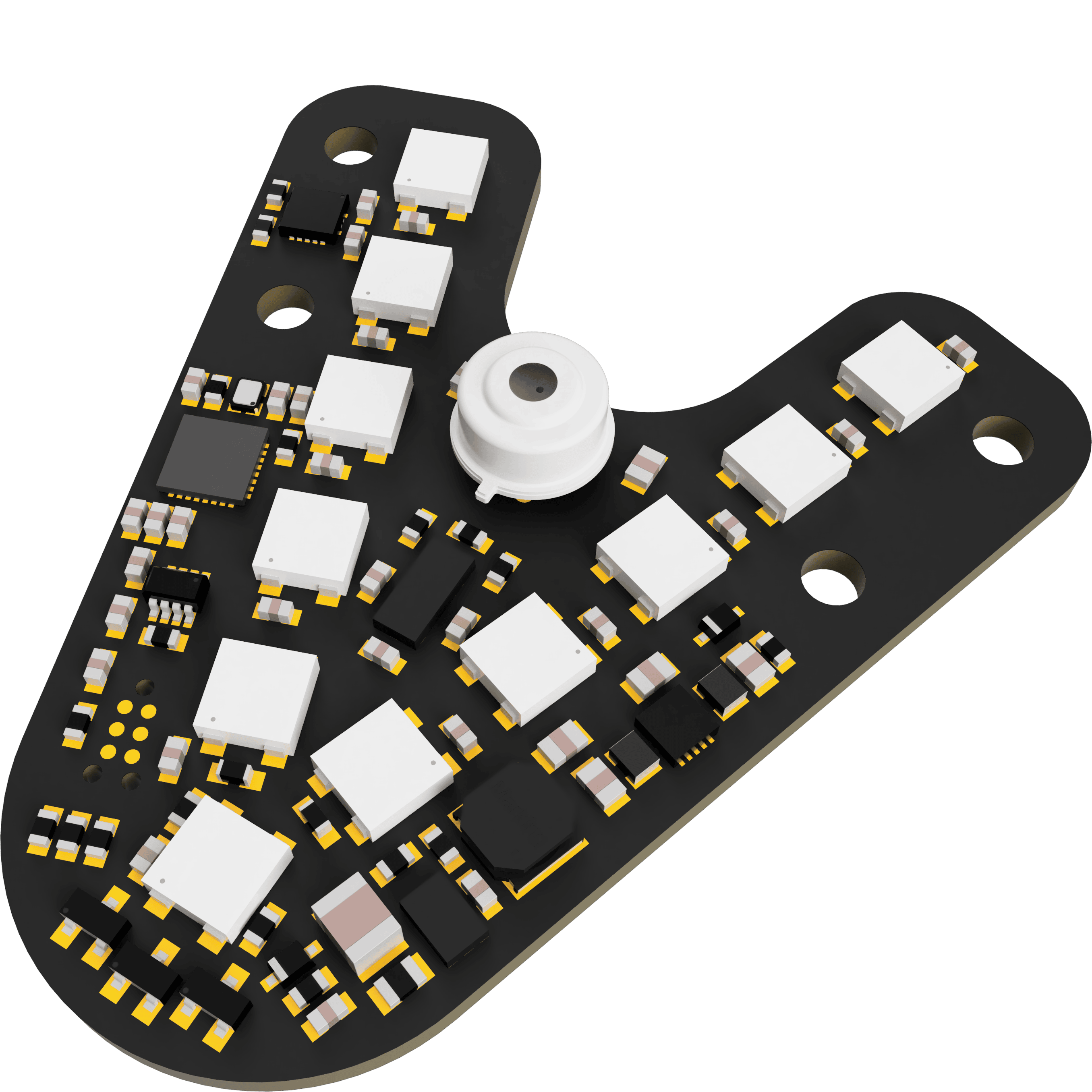

Edu Headlight

Frontlight of the EduArt Raspberry Bot, equipped with a Time-of-Flight sensor and an optional thermal camera.

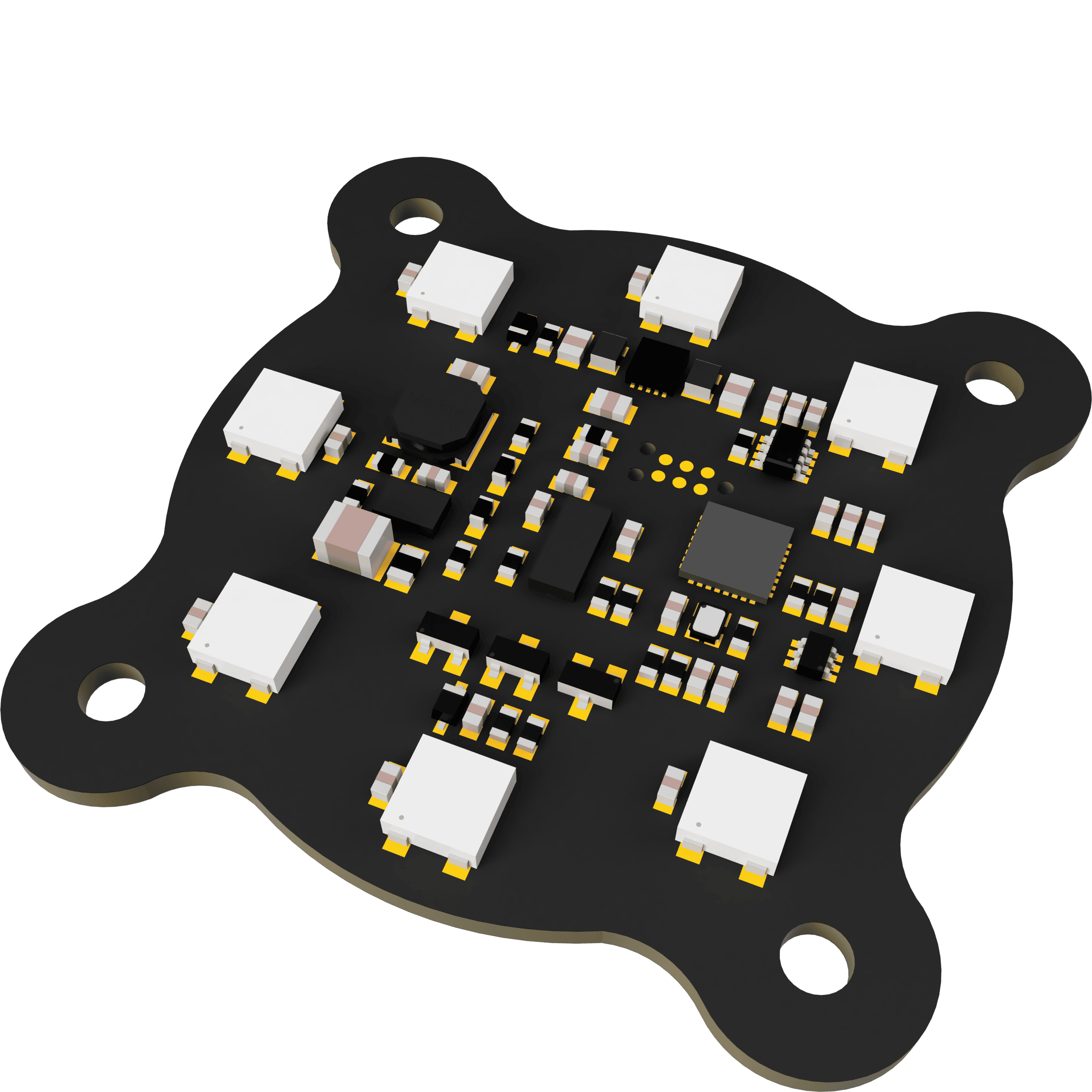

Edu Taillight

Backlight of the EduArt Raspberry Bot, equipped with a Time-of-Flight sensor.

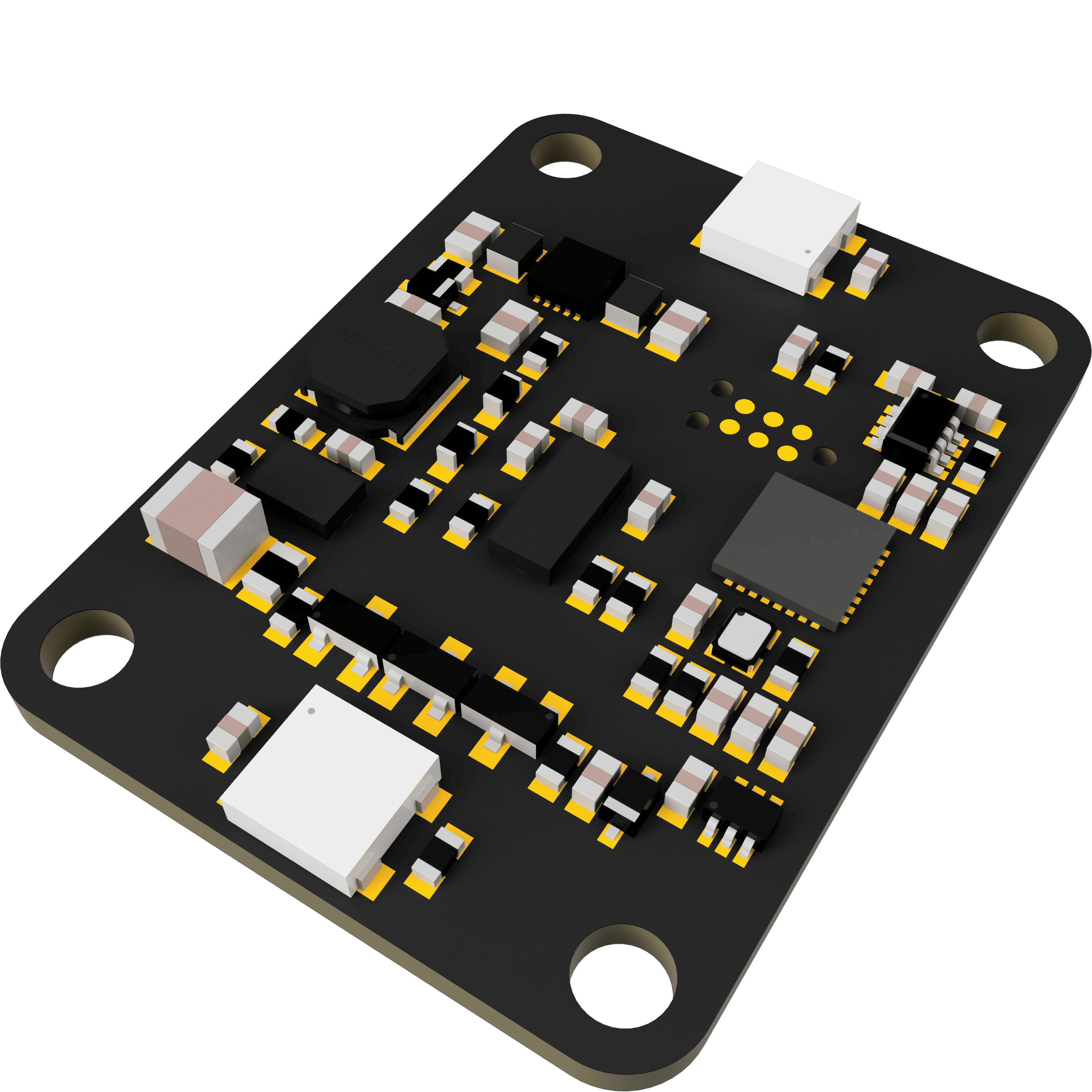

Edu Sidepanel

Compact All-in-One Module (38 × 28 mm) with RGB LEDs that can be used on any robot.

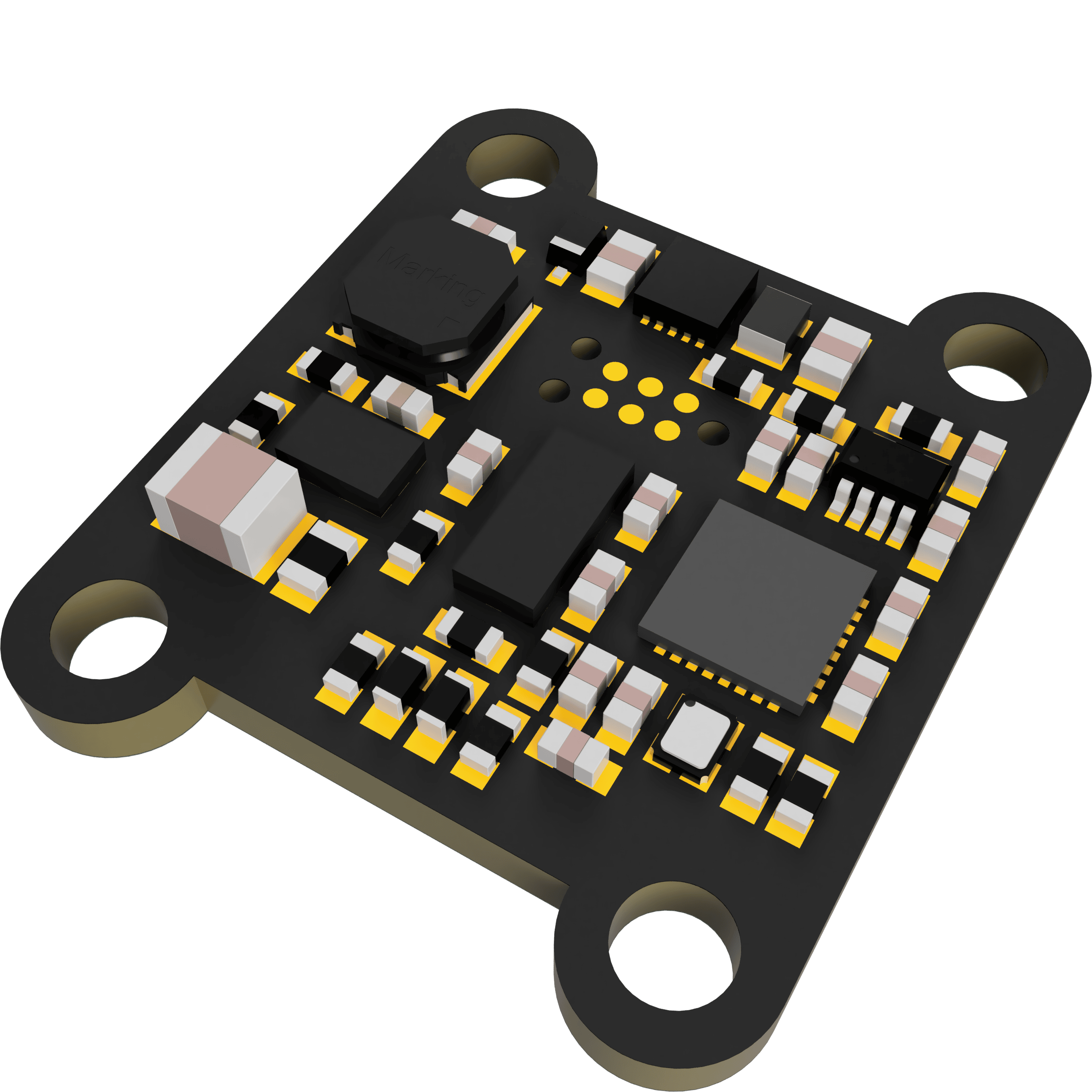

Edu Minipanel

Even more compact All-in-One Module (28 × 24mm), comes without RGB LEDs but is small enough to fit in every robot.

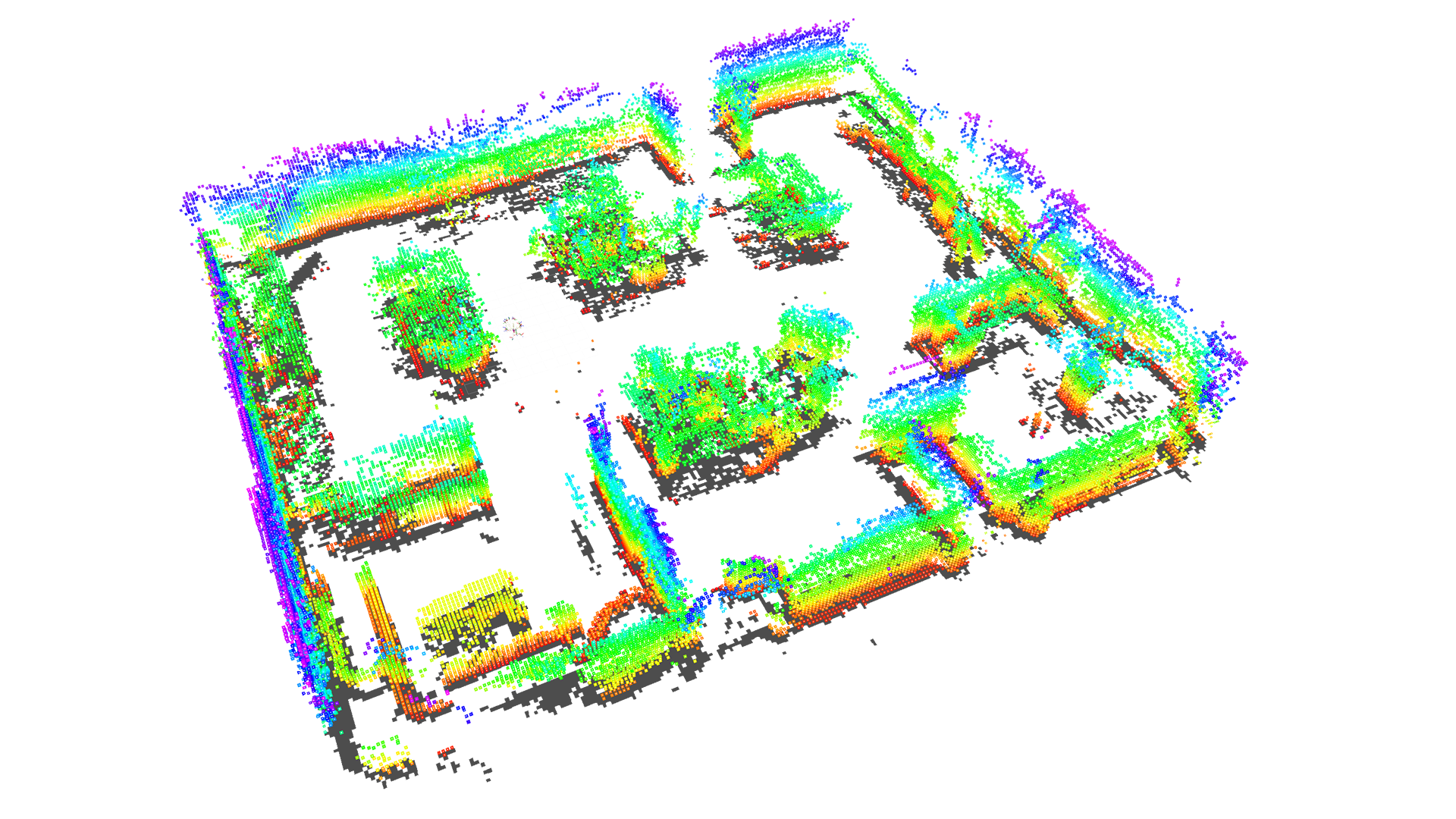

high-resolution 3D vision

The illustration shows image and environment data processing using a ring of ten Vision360 ToF (Time-of-Flight) sensors. These sensors accurately measure distances to objects by calculating the time it takes for emitted light to reflect back to the sensor. The collected measurements form a three-dimensional point cloud, where each point represents an exact position in space. The colored visualization highlights detected obstacles and structures, providing an intuitive view of the surroundings – ideal for navigation, collision avoidance, and detailed mapping. Depending on application requirements, more or fewer than ten Vision360 modules can be arranged in the sensor ring to achieve the desired coverage and resolution.

Compared to conventional LiDAR systems, Vision360 ToF technology offers several clear advantages. Its compact and modular design allows sensors to be placed exactly where they are needed, eliminating blind spots and enabling flexible coverage. Traditional LiDAR often relies on bulky, mechanically rotating units with a fixed field of view, whereas Vision360 provides instant 360° situational awareness without moving parts – resulting in greater durability and lower maintenance. The distributed architecture also makes the system scalable and cost-efficient: you only install as many modules as required, reducing hardware costs while maintaining high-resolution, real-time 3D mapping. This flexibility, combined with seamless data fusion, ensures reliable performance in complex and dynamic environments where standard LiDAR may struggle.